I have worked the last 13 years mainly in the design side of the nylon tactical gear industry. I have seen the trends go from LBVs to plate carriers, to micro rigs, to belt setups with suspenders, to belt setups without suspenders, to recce rigs with hundreds of in-between products along the way. Entire companies have sprung up just to invent and manufacture interface devices to smash multiple pieces of industry gear together. I have even been responsible for some of them. These days you can find a piece of gear that will fit just about any mission that you might have. In the event you can’t, there are tons of smaller custom builders (like me) that can produce your one-off project to exact specifications.

But what is the next leap? (And I don’t specifically mean in materials). You could call going from regular old Cordura to laminates and hypalon type materials a leap as it is a much better material to laser cut, but the build process is pretty much the same (i.e. you sew it together to make pockets). I’m talking about the next evolution in textile production – not just for the tactical gear industry, but that is where my experience comes from. I believe it is going to be in the world of 3D printing. That is, 3D printing the fibrous materials in a full (or nearly full) constructed state. Like, hit go on the printer and come back to a finished plate carrier a while later (perhaps a long while). Why would it be with a fibrous material? Today’s fabrics do a really good job of arresting a rip or tear before it gets too bad. This is sometimes referred to as “Ripstop”. This is accomplished by the weave of the yarns that make up the fabric. There’s no reason to throw that away. If you were to print solid flexible sheets instead there is a good chance that a “rip” would continue on over time (perhaps a short amount of time) and eventually render your equipment useless. And I’m not talking about just another plate carrier like we have today. What comes out of this theoretical fabric printer could be a design that contains build geometry that could not be produced on a sewing machine.

Part of my business is building custom solutions for individual soldiers, police, contractors, and larpers. Sometimes those customers will send drawings of what they have in mind. However, they lack the experience of being a stitch-operator like myself. They may not realize that their drawing can’t be made the way they have envisioned it.

For instance the attachment of a piece of fabric to form a pouch on one side might sew another pouch shut on the opposite side of the work. A good gear designer can usually find a way around this, but the situations do get complicated – especially when you consider a lot of these pieces go together in reverse and inside out. It’s a lot to get your head around until you have some time in it. However, most of these concerns would vanish if instead you are building (or printing) your gear a cross-section at a time. Layer stacked on layer of slightly varying geometry resulting in a perfectly reproducible piece every time.

Think about it: no hems, no seems, no need to have extra material folded over to help prevent the threads from pulling through a high-stressed area. Do you need an area reinforced? Simply tell the operating software that “this specific section of the design needs to be stronger” and let it do the work.

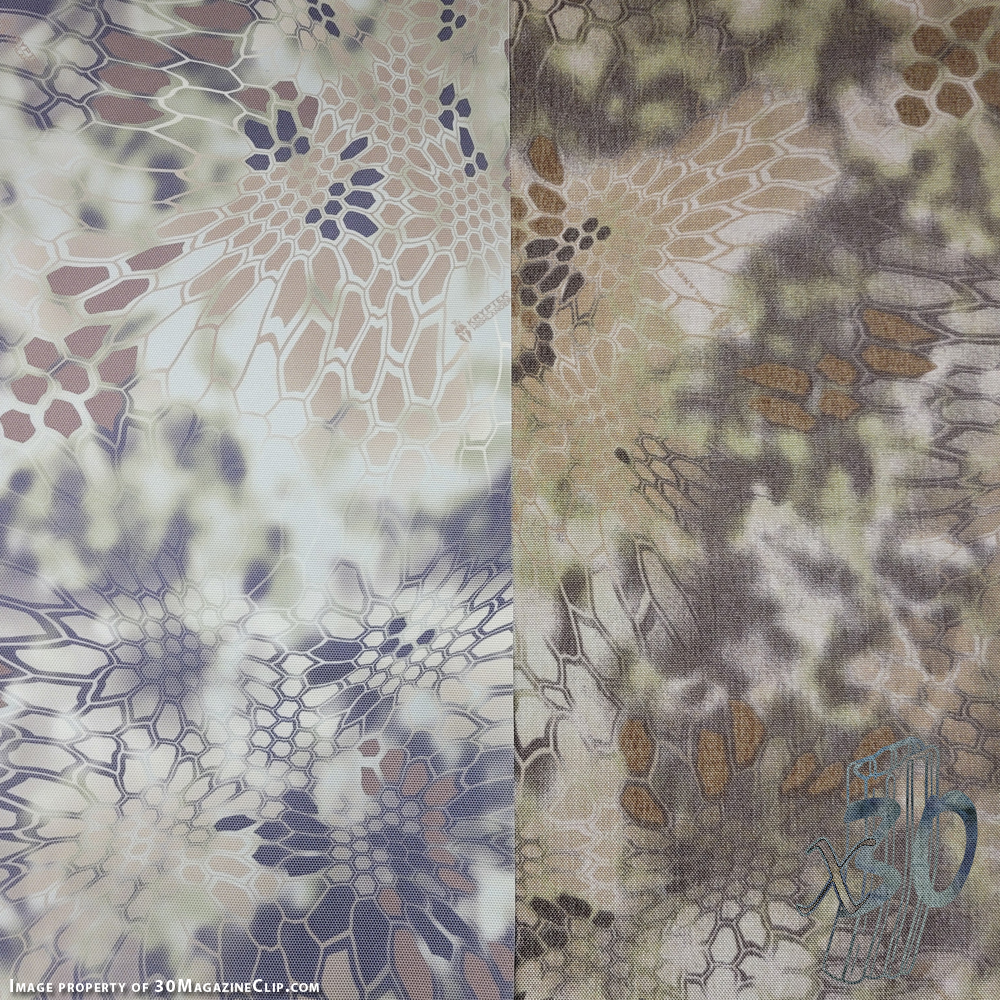

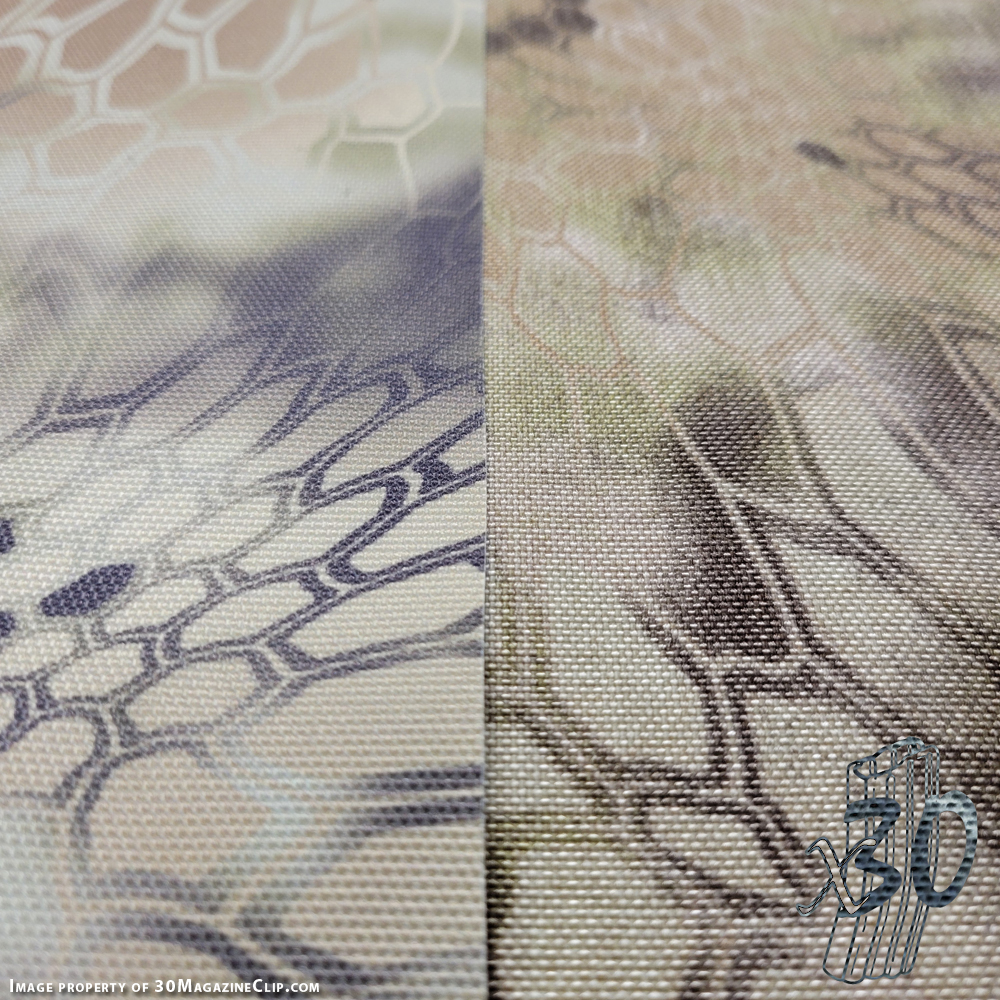

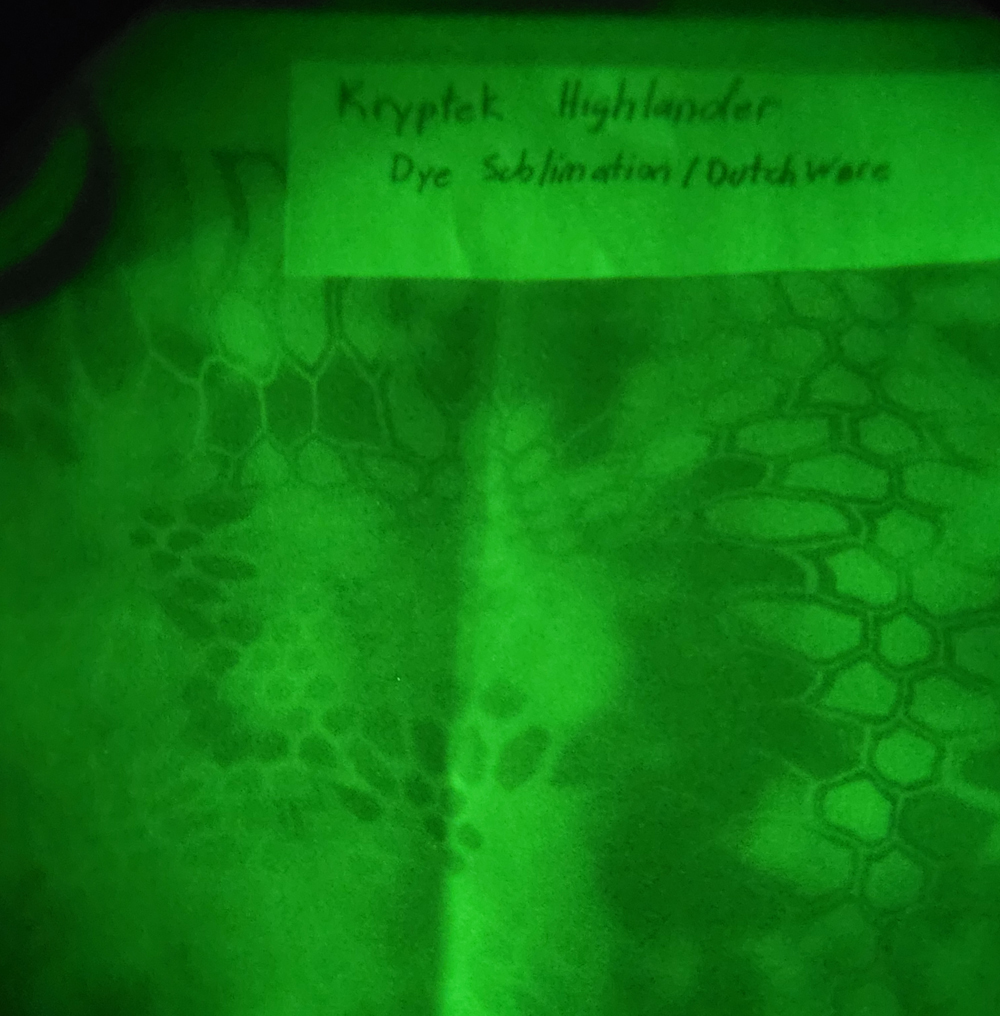

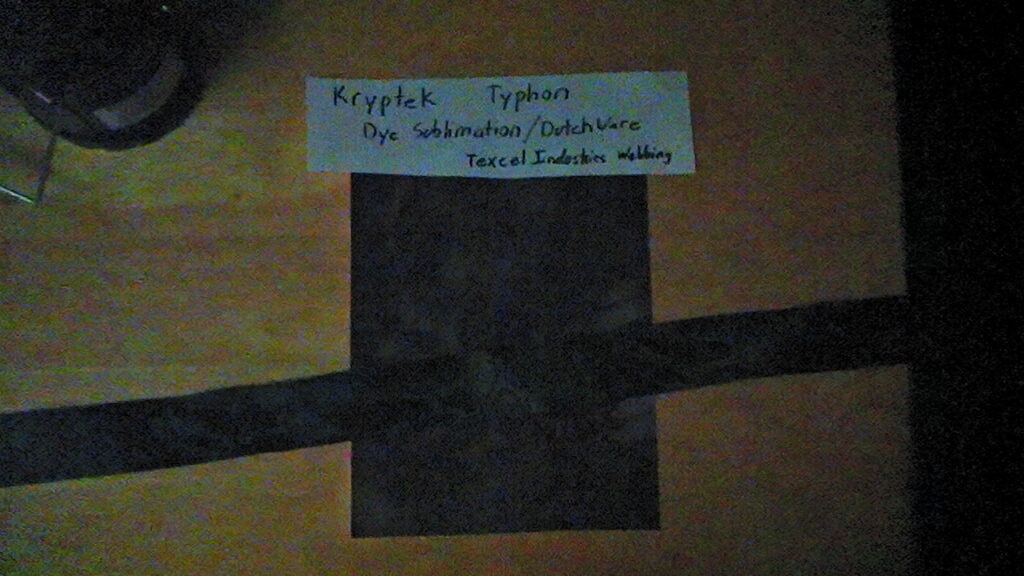

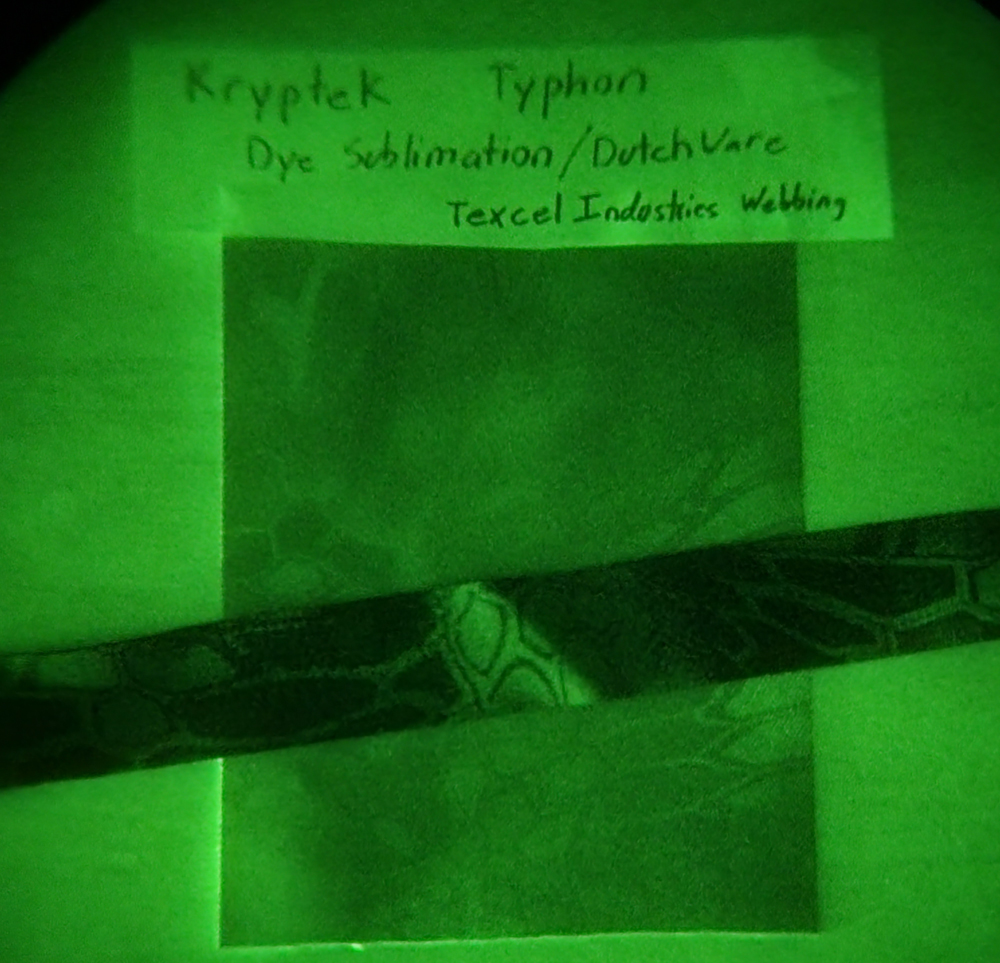

What about the camo patterns?

Just print them, too, like everything else. Now, I know this isn’t a viable option yet, but I am fairly confident that once the industry figures out how to reliably print the fibrous nylon material to a high degree of accuracy, varying the color of each layer and area in that layer will be an afterthought. We do it with 2D printers all the time.

Continue reading Where is Tactical Gear Production Headed? →