So you want to start sewing your own tactical gear? That’s great. The first question you are going to have is probably, “what type of machine should I get?” If you are serious about doing this you need to be able to sew multiple layers of Cordura-like fabric. You can just skip the plastic Wal-Mart special for $99. It won’t do what you need it to do and you will have just thrown that money away. In this write-up, I am going to layout my first hand knowledge after 14 years (at the time of writing) being in the tactical gear industry. I have not been paid or compensated for ANY of the recommendations below.

What type of sewing machine should I get for “tactical gear”?

First thing is first. The type of machine. What you are probably needing is what is referred to as a commercial sewing machine. Some will refer to it as an industrial sewing machine but I believe “commercial” is the correct term. I will talk about the specific machines I have the most time on below.

Commercial machines come in a few different flavors. Some (more expensive) are computer aided or controlled. Some are straight up manual/mechanical (which I will mostly talk about here). Some are servo motor controlled while others are clutched.

There are a few things that I am just going to come out and say. You can thank me later. Get a server-motor machine with a compound feed. Servo-motor refers to the motor actuation. When you are not sewing it is not spinning. As you press the foot pedal (gas pedal) it starts spinning proportionally to how much you are depressing the pedal. Fairly self explanatory. A clutch motor is always spinning at its efficient RPM and uses the clutch connected to the foot pedal to engage and transfer that power to the sewing mechanism in the head unit. While not impossible the clutch motor system is much harder to get a handle on. As for my second “just do this” piece of advice, the compound feed. This refers to how the machine pulls the fabric in (feeds) between each stitch. The “compound” signifies two things (in no particular order);

- It is a walking pressor foot.

- It is a needle feed.

The walking foot is pretty easy to spot. The foot (that little piece that holds the fabric down and the needle shoots through at great speed) is two parts. As the machine advances it basically “walks” the fabric in. This greatly helps with bringing the fabric in smoothly as it is matching the movement of the feed dogs below on the underside of the fabric. This keeps your multiple layers of fabric in position while feeding.

The needle feed just means that the needle itself moves forward and aft during the cycle of the machine. A sewing machine tech would be able to explain this part better but it basically makes the needle a part of the feed system. It just works WAY better. Also, your fabric layers aren’t going to move in relation to each other if there is a giant needle pinning them together while feeding.

Needles

First rule. If you blunt a needle (the sharp tip gets rounded due to an impact on something it shouldn’t have hit) change it. You will be tempted to keep going when your needle is no longer sharp. But trust me. The entire system works better with a sharp needle.

Odds are you are working with a DPx17 needle system. Personally I use a size 22 needle for just about all of my Cordura work. If you jump on Amazon to purchase needles and see 135×17 DPx17 Size 22 then that is what I am working with. I find it works great with just about everything “tactical”. But don’t just buy those without checking to see what your machine is setup to run.

Thread

Thread is another important factor in building your own gear. I use a Size E or #69 (A-A-59826A spec) bonded Type II nylon thread. With a size 22 needle (above) this combo just works for tactical gear. Pretty much the only time I would go up in thread size is if I was making climbing gear. As that is not my specialty I will leave it alone.

My thoughts on the matter

Everything I have said above is my opinion. I have quite a bit of experience so I think it has some value. But you will develop your own preferences as your skill increases. What I do know is that with the combination of gear that I have described above you can make just about any tactical piece you desire; belts, plate carriers, slings, chest rigs, load bearing equipment, and accessories to support all of those pieces.

When you get started you are going to feel that sewing is hard. Don’t worry though. Sewing on a commercial machine is not hard. It is just technical. Meaning you need to develop your technique. The only way to do that is with time in the saddle. You can watch YouTube sewing tutorials for months but until you sit down in front of the machine you will develop no skill.

Sewing is basically a partnership between you, the machine, and the work (fabric). Don’t try to man-handle it. Figure out how your machine likes to work and then “instruct” your machine. Don’t try to force the fabric to feed how you want it. Just direct it and let the machine do the hard work.

Let’s talk safety for a second. Just as Nicholas Cage described the VX gas to Sean Connery in THE ROCK, “The second you don’t respect this.. it kills you.” Well maybe not kill you. But it will sew the crap out of your hand. When I am training new stitch-operators I always use the following guidelines.

- Treat the machine like a gun. It isn’t a toy.

- Keep your feet off the pedal until you are ready to

firesew. - Don’t watch TV while sewing.

Some first hand machine knowledge

The first machine (of note) that I owned was a TACSEW T111-155. This machine was GREAT! A real workhorse. Completely manual (except for the server motor). No automatic thread cutting. It just stitched until I got tired every day.

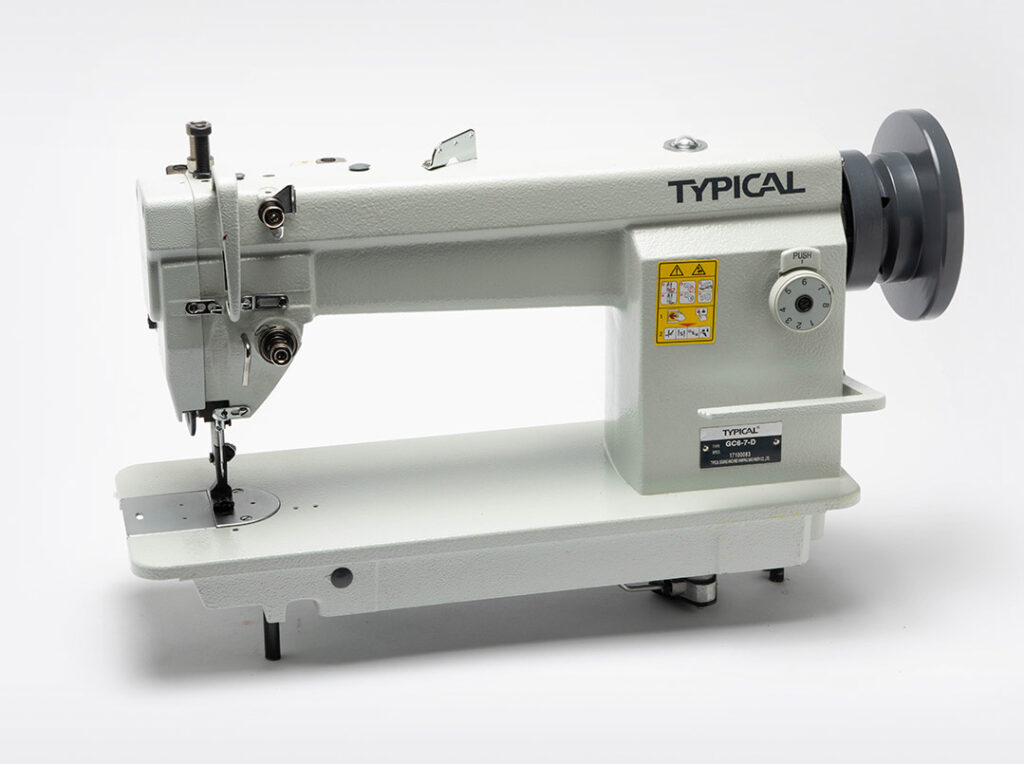

The TACSEW line stopped being produced a few years ago. I heard they sold their commercial line to CONSEW but I have nothing to back that up. That’s ok though as the TACSEW was basically a direct 1:1 copy of the TYPICAL GC6-7-D. When I needed a new machine for a second operator this is what I got. I still use this specific model today. More info on that later.

I used the SUNSTAR KM-3420BL-7 for a while. This is a much more complicated machine (has a computer) but added a TON of features. Automatic thread cutting/trimming, direct drive motor (no belt driven motor under the table), the pressor foot lift control was part of the foot pedal instead of a separate knee control. A truly impressive machine. This specific machine is making a huge impact on the tactical gear industry right now. Especially the smaller producers out there. I had one in the office for several months but actually ended up letting it go. The following are just my personal thoughts and are actually shared by very few other stitchers out there. I prefer manual. I’m just really fast due to the time I have sewing on a manual machine. Automatic thread cutting is great but I typically sew with my thread scissors/nippers in my hand. So, I am not searching for them when finished with a line of stitches. This means that the auto thread cutting feature saves me a very small amount of time and on occasion it will mess up the process. I then have to stop and rethread the machine. For me, manual is the way to go. You of course are looking at a price increase when you get to computer controlled/aided units.

Personal recommendations

I have worked with a few personalities in the commercial sewing industry. Below are the top 3 (in no particular order) that I have personally bought equipment from.

- Collier Equipment. www.CollierEquipment.com. Robert Collier 256-229-6595. These guys are great and really know their stuff. GREAT customer service. Robert really wants to form a relationship with his customers. He will go the extra mile for you.

- Sewing Gold / Goldblatt Sewing Machines, Inc. www.SewingGold.com Steve Levin 773-486-1779. I have bought 3 machines from these guys. Steve has spent a good amount of time on the phone with me answering questions. He is always happy to do it.

- Nick-O Sew Machine. www.Nickosew.com. Nick Pittman 731-443-3414. New machines and refurbished are available here. Nick has extreme levels of knowledge on the subject.

Either of the outfits above will be able to help you with commercial sewing needs. I hope this write-up helped you out and good luck on your journey to becoming a stitch-operator.