This review is mainly targeted at the DIY tactical gear makers out there. Anyone from the hobbyist to the guys running side gigs making gear out of their basement, garage, extra bed room. If you fit into this spectrum then you have probably considered getting a digitally automated hot/cold webbing cutter for your shop but cringed at the prices.

What exactly are we talking about here?

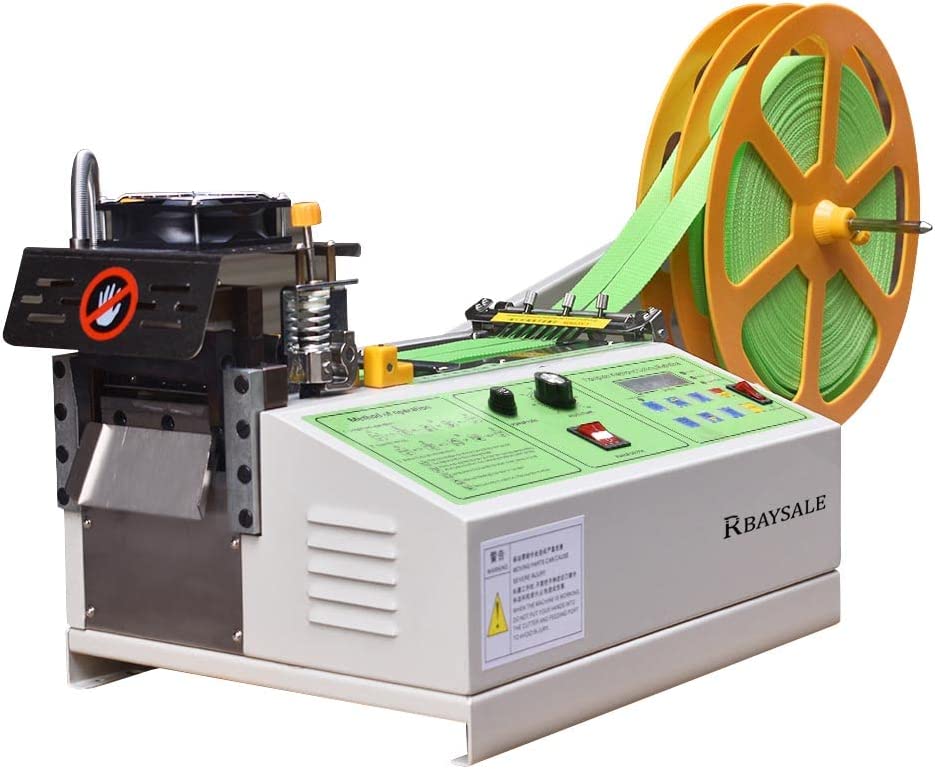

Let’s start with a link to the actual machine we are referencing. The Rbaysale: Webbing Cutter Machine, Automatic Hot and Cold Tape Cutter for blah blah blah. I purchased this unit in November of 2019 and have used it extensively over the past three years. From the pictures I see now it does look like there have been some improvement’s made. Mainly that the dominate writing on the unit (button descriptions, readouts, etc) seem to be primarily in English now. On my unit the Chinese characters dominate and the English is a physically small afterthought.

So how much?

When I purchased this machine in 2019 it was listed on Amazon for $599. I then paid $150 shipping for a total of $749.00. The base prices seems to now have fallen to $579. Not exactly peanuts but when you compare it to the price of a Sheffield (the industry gold standard) or a Nova Tech International it makes you think twice about saving some big money that could be spent on other equipment. And just to be clear. I did pay full price for this piece. It was not given to me for review.

But the truly impressive thing about the ordering of this machine was the speed at which it arrived. The order info and shipping label gave every indication that this piece of equipment was shipped FROM China. Yet it arrived faster than some domestic orders that I have placed. We are talking 4-5 days. Outstanding, really.

What can you expect?

First off let’s just be up front. This is NOT a Sheffield cutter. Don’t expect it to be. I have used both and the Sheffield blows it away in every category I can think of… except price.

Functions

The cutting width is a bit limited at 3.7″. Hot and cold cutting are both included options (no knife changing needed). Normally you would cut hot on nylon webbing, loop Velcro (to get through all those individual strands cleanly) while cold cutting would mostly be used on things such a hook Velcro. There is a dedicated power button and then another switch to control ONLY the heat circuit. A dial also allows you to “dial in” the correct temperature to best cut your material. This can become kind of tedious. You will figure out fairly quickly that the range in temperature between NOT cutting your webbing cleanly and the hot knife blade smoking as it burns off any nylon remnants stuck to it is a very fine line.

The included and adjustable guides are fairly well thought out. You can set the unit up to cut just about any width (up to the max) and even cut off of multiple rolls at a time (see main image above).

Biggest disappointments

There are a few things that always come to mind when telling others about this machine. #1 It will NOT measure elastics correctly (for me). Other people have told me to turn down the speed. I have tried that with no change. Something about the metering roller (measures the material as it is being passed through) does not work correctly with elastics. I am speaking of the MIL-W-5664 elastic and 1/8th” shock cord which are the only two I have attempted. This is frustrating because it does say on the Amazon page that it will cut elastics.

Second, the hot cutting feature DOES NOT completely “seal” the fraying materials enough (when using MIL-W-17337 and A-A-55301 spec webbings). If I am cutting webbing that is going to have a raw edge exposed I WILL have to then hit it with a torch to complete the searing process.

Third, NEW webbing rolls cannot be left alone on the dispensing arm when cutting. A 100 yard roll is bigger in diameter than the three included “disc guides” (the orange things in the picture above). While pulling the webbing off of the roll it will try to pull it off sideways every once in a while. It will continue to feed the webbing to the cutting portion but will eventually pull it in with a fold since it did not come off the roll correctly. You will then be tempted to walk away and accomplish something else as soon as the roll shrinks to the size of the disc guides. But don’t just yet! Since the machine kind of jerks the webbing in quickly (it’s trying to go fast) there is a bit of a “rebound” when it stops to cut. The webbing roll then continues to unwind a bit and can “jump off” the roll sometimes which results in the same situation. Do yourself a favor and don’t take your eye off it until the roll is ~80% used.

Fourth, there is no number key pad. Basically all you are entering into the machine are numbers. Quantity, speed, length, etc. A 10-key number pad would be a MASSIVE upgrade. Instead you are forced to hit the “Length” key. Then go up and down by digit. Then push a button to move over to the 10’s. Do the same. Move over to the 100’s and so on. You then have to do this process for the “Quantity” setting. It would be so much easier to just punch in “124” to get so many pieces. You do end up getting pretty fast at this but in the beginning of owning the machine it will take a bit of time to get your variables entered.

Failures

The only failure was the fuse (unless you count the elastics too). There are 2 operating fuses on this machine. One is installed into the power port on the back where the cord is plugged in. The other is located on the front plate (where the controls are) and I think is specific just to the heating unit. The unit came with a T5A250V fuse in the power port on the back. There is also a spare inside of the power port on the back. One day about a year into owning this particular cutter the main fuse blew. I had the cutting tool heat turned up a little higher than normal so I just figured I had pushed the limit a little bit to much and the fuse did its job. So, I installed the spare fuse, turned down the heat to my normal setting, and continued. Within 30 seconds it had blow the second fuse. The only other fuse of the type I had was a T15250V and I needed to get this material cut so I stuck it in and figured I wouldn’t take my eye off of it. That worked and it is still running on that fuse to this day. This might not be advisable but like I said I don’t leave the machine while it is running and I physically unplug it from power when not in use. Otherwise the entire machine is just a big paperweight at this point with the standard fuse so I don’t really have another choice other than using a larger fuse.

Conclusion

This machine is cheap. As I said before it is not a Sheffield so don’t expect it to be one. For the guy who has just enough material to cut to cramp up his hand I would recommend this cutter. It checks the boxes I needed and it didn’t break the bank. It is probably used around 3 hours per week and is still running approximately 3 years later. It has paid for itself many times over and makes life a bit easier for me. With that said… I would recommend this unit if it fits your need.

If you have any questions about this machine feel free to leave comments below or message on the 30MC social media channels. I will answer any questions if I can and include them at the bottom of this post for others. Thank you for reading!